CUSTOM MACHINE DESIGN

Product Gallery

Innovative Solutions for Complex Machinery Needs

Dive into the world of custom-engineered machines designed to push the boundaries of precision and efficiency.

Since 2002, customers across the U.S. and other countries have trusted Wisconsin Custom Machinery, Inc. for a range of custom machine design and build services. We offer complete solutions for our customers and our team has over 80 years of combined experience.

We specialize in small and medium-sized projects and are known for our commitment to customer service and rapid turnaround times.

MADE FOR YOU

For all your machining requirements, choose our team at Wisconsin Custom Machinery Inc and experience the true difference.

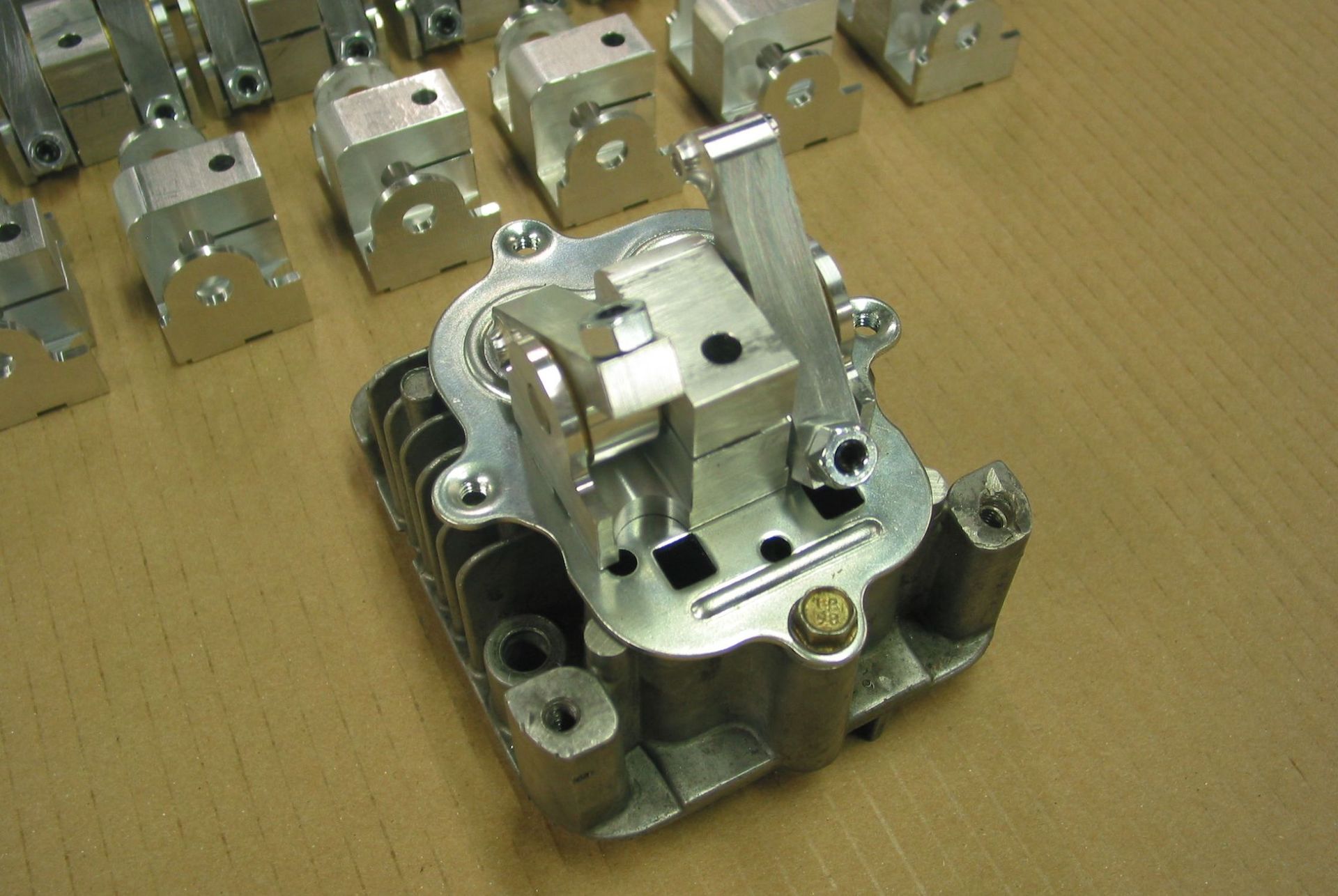

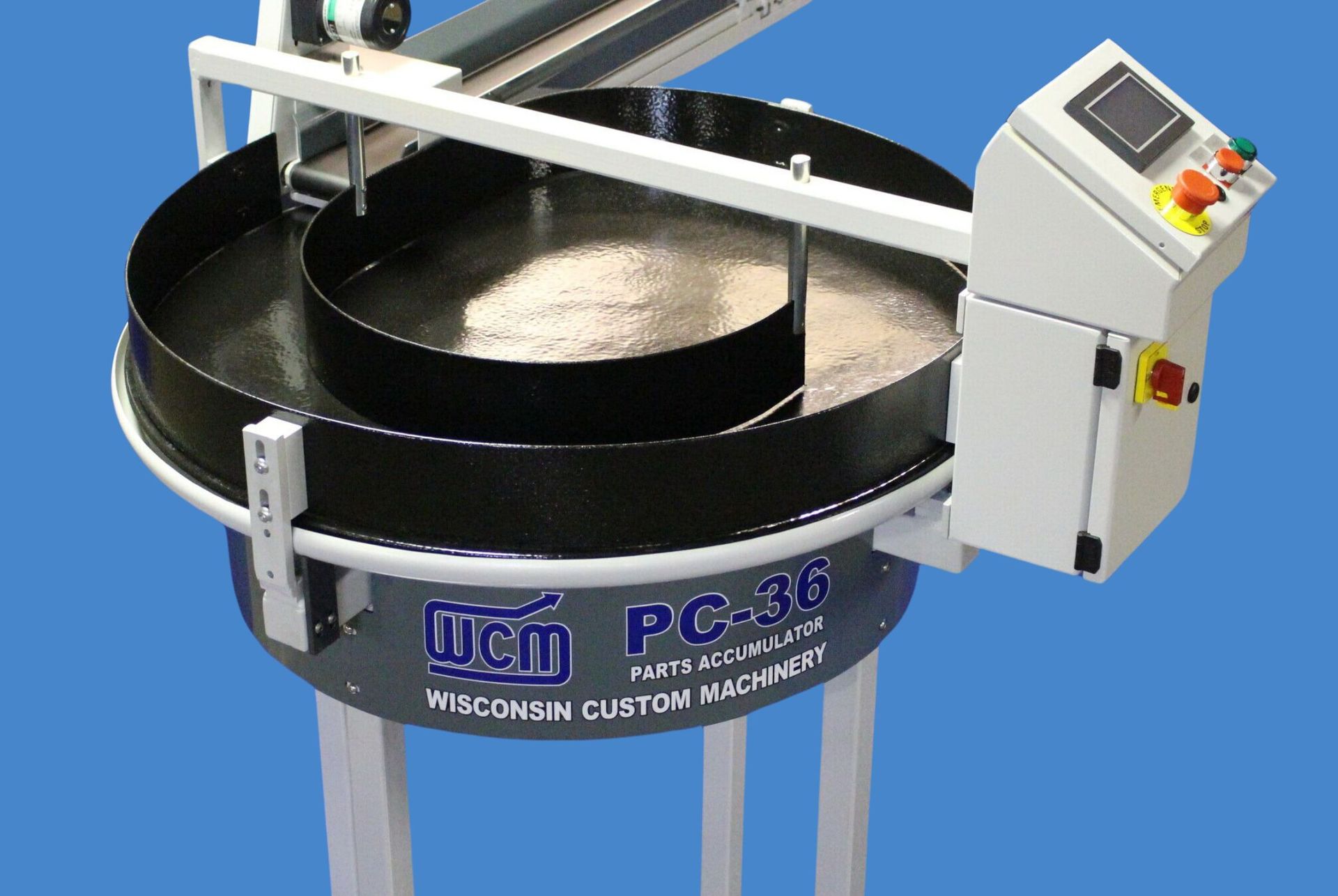

Parts Accumulator

The parts accumulator is used to accumulate and protect finished parts discharging from CNC lathes. It comes in sizes 24", 36″, 48″, and 60″. It is left or right hand rotation, and has adjustable legs for 12″ to 50″ height. The parts accumulator is PLC operated with HMI for setting parameters (The optional belt conveyor is available in multiple lengths).

Can be built with dual lanes to accept parts from two CNC machines. Table may have fences or come with separate pockets to keep parts in sequential order and from contacting each other.

Single End Tenoner

WCM's Single End Tenoner offers precision single end trimming and coping with 1-4 tooling stations. It features a 12" wide table and carriage on linear bearings, manually or automatically operated via electric drive. Preventing double passes, the table retracts after each stroke. It includes two pneumatic hold-down clamps, a swivel fence for miter cuts, and a flip-up stop with digital readout for cut length.

Tilting Plate Saw

The tilting plate saw is a semi-automatic metal cutting band saw that traverses the length of its table. The saw head tilts from 90 deg vertical to 30 deg backward, and it’s height capacity is 14″ with 80″ of cutting travel length. It has a 1 1/4″ blade with a T slot work table for clamping. Head tilt is hydraulic while saw travel is servo driven with variable rate.

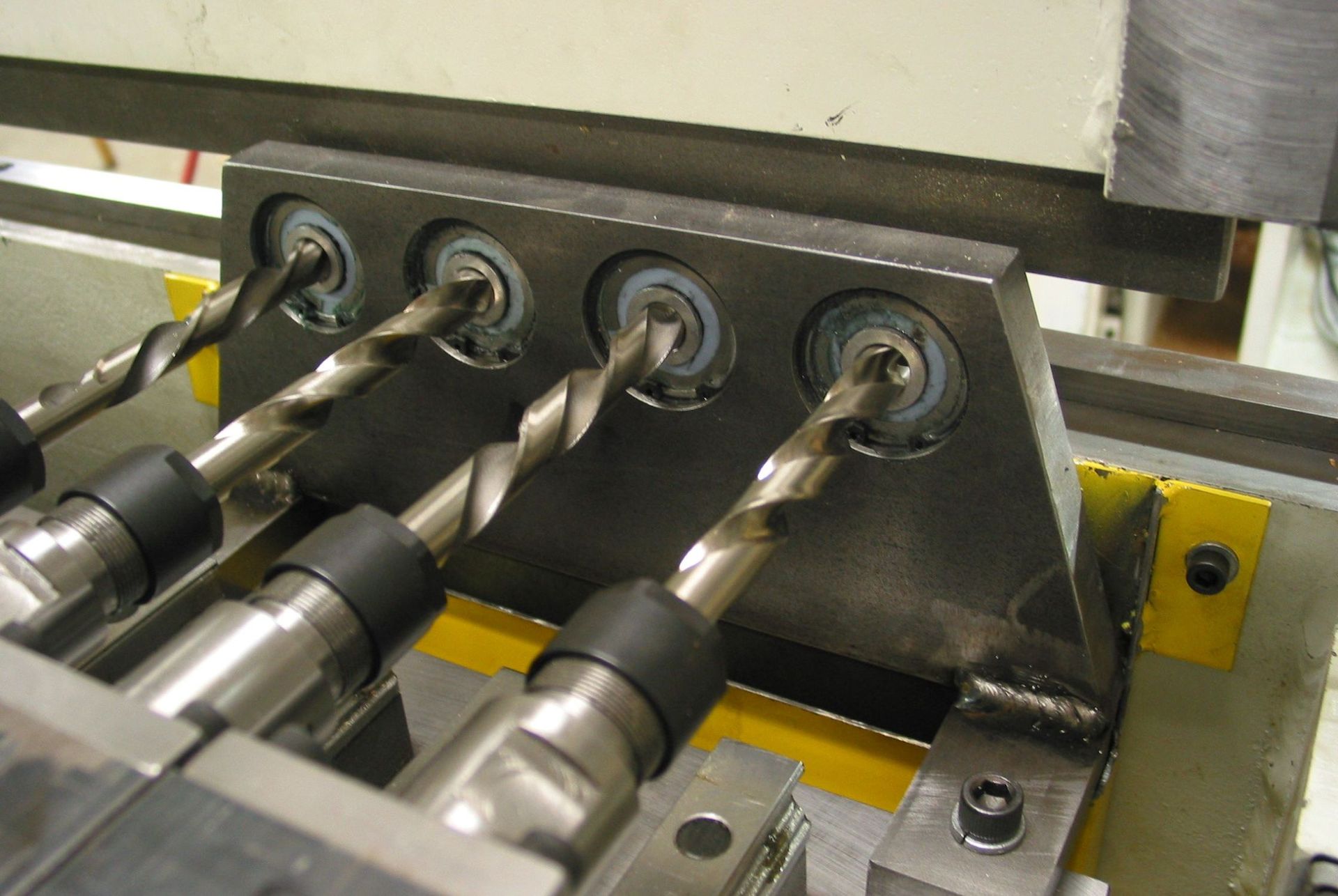

Tube End Finisher

The Tube End Finisher simultaneously end faces and chamfers ID and OD edges. Tube size change over time is 45-50 seconds using interchangeable BT-40 style cutting heads and clamp jaws. Tube capacity is 1/2″ – 3″. O.D. The chamfer size is adjustable. The cutter head is completely guarded for safety and has foot pedal operation.

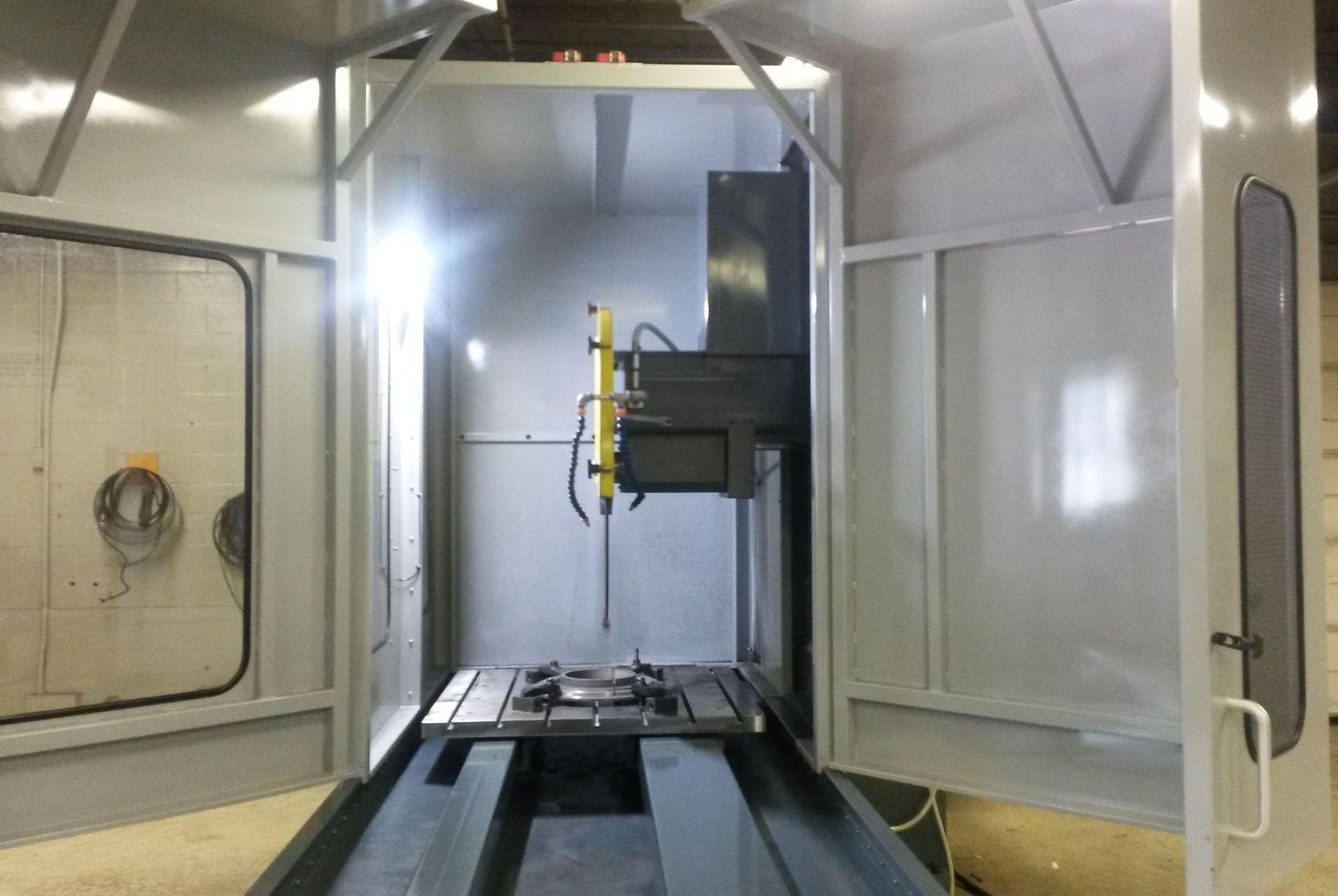

CWS-20 Wet Saw

CWS-20 Wet Saw is a 15 HP custom circular wet saw for fixture cutting of components on a heavy 36″ x 24″ T-Slot table. The enclosure doors open and table extends out for easy loading. 20″ diameter blade capacity with flood coolant and semi automatic operation.

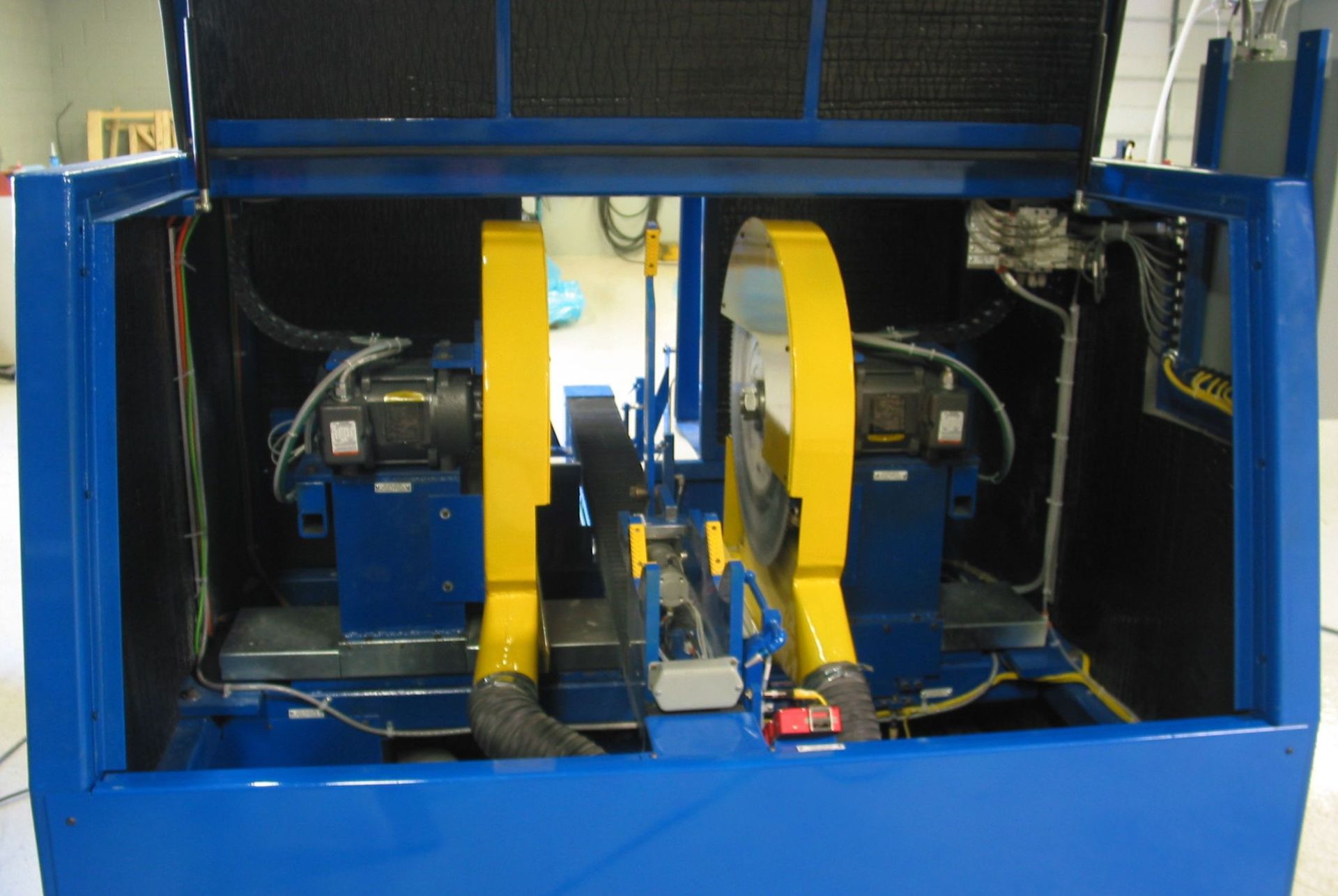

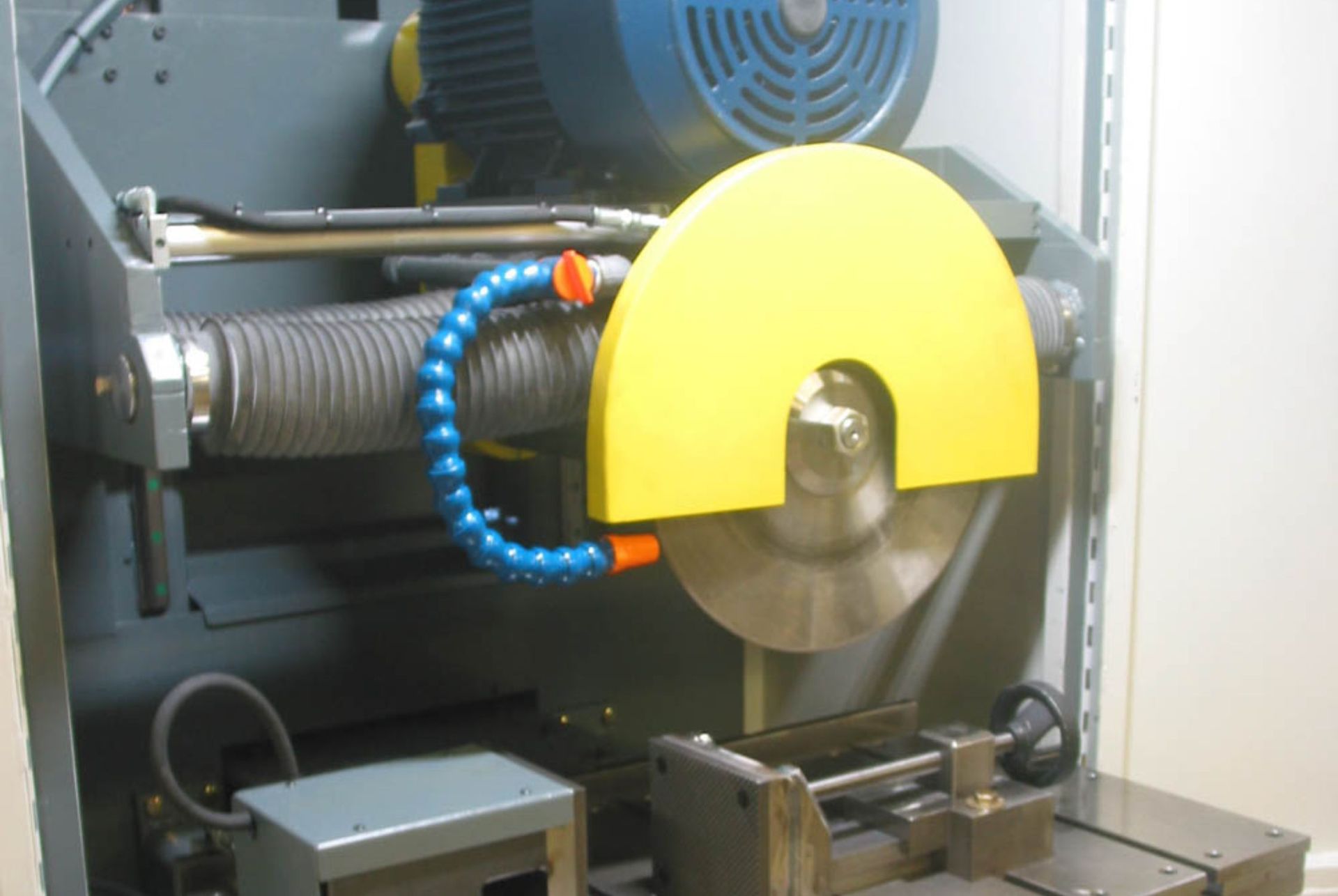

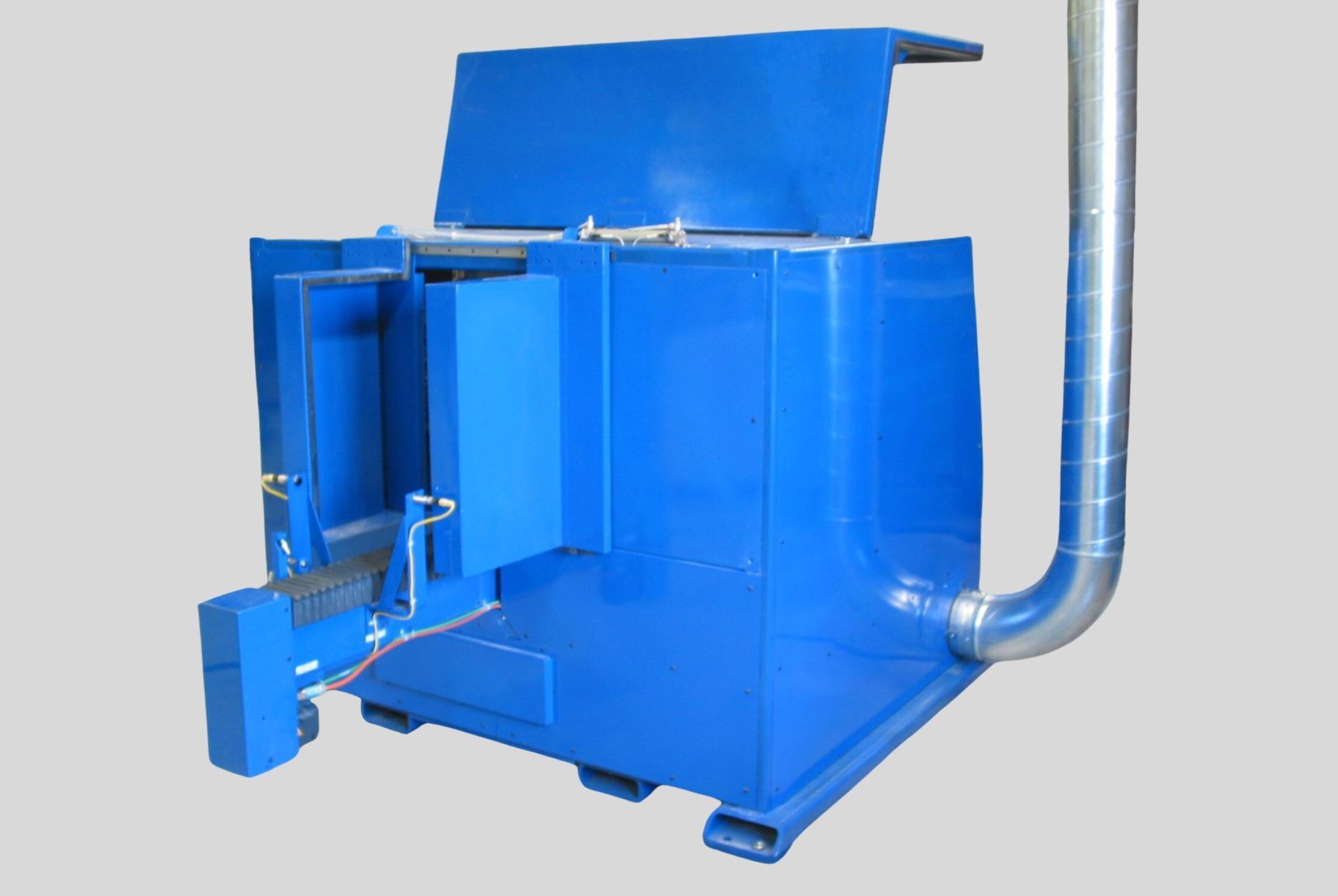

PWS-44 Abrasive Saw

The PWS-44 Programmable Abrasive saw has a 40 HP or 60 HP blade drive motor and 24″ to 44″ blade capacity This machine has a 48″ x 48″ load table with T-slots. The saw has 84″ of “X” table travel from left to right, 26″ of head “Y” travel, and 20″ of head “Z” travel. The machine is fully enclose with flood coolant and filtration.

Challoner Tenoner Rebuilding

Wisconsin Custom Machinery boasts expertise as a seasoned rebuilder of Challoner Double End Tenoners. Our services extend to chain rebuilding and replacing common wear parts, such as hold-down belts, pads, drive chains, and sprockets. Additionally, we specialize in enhancing machinery with automation upgrades, ensuring improved performance and longevity.

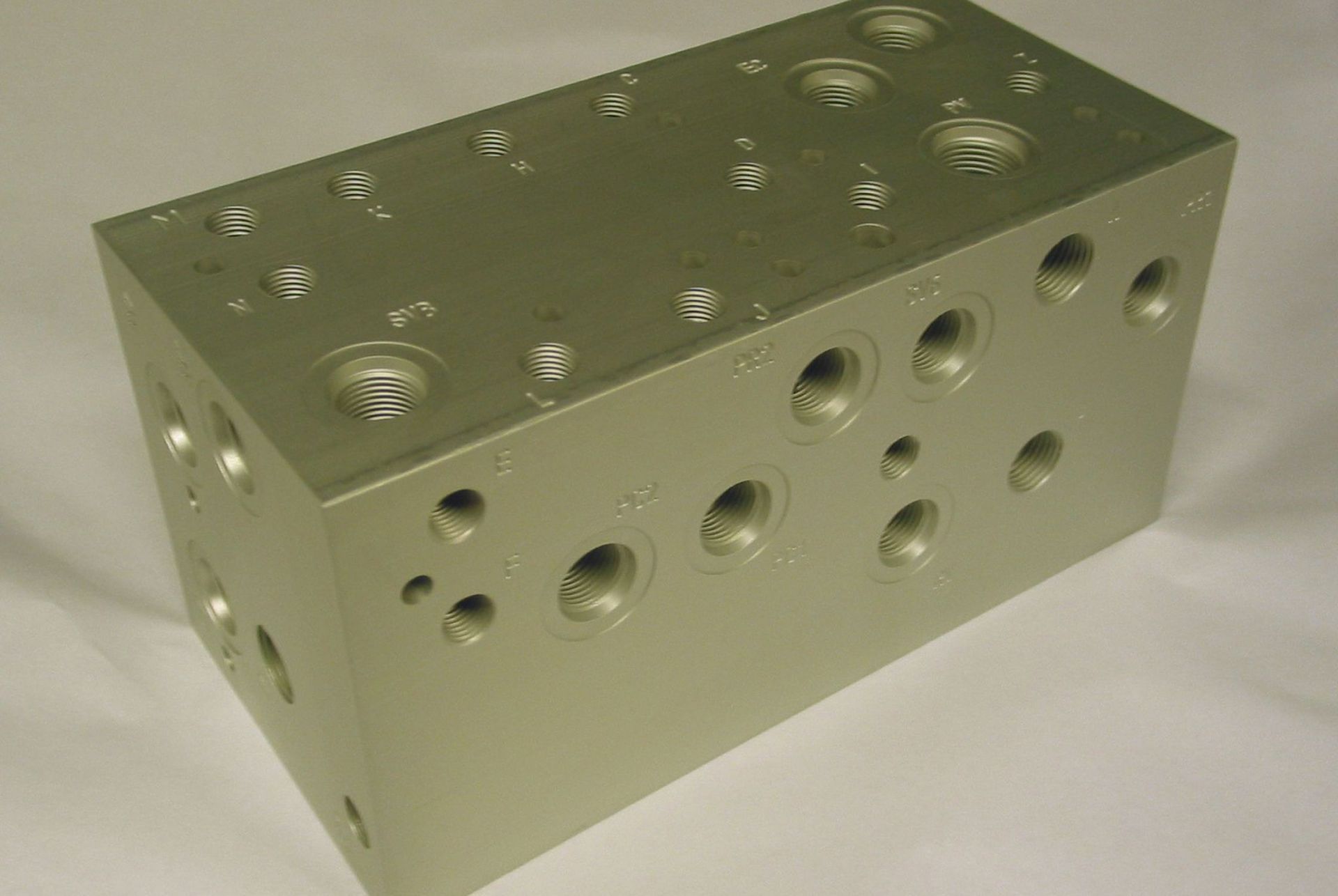

Custom Double End Trim Saw

WCM crafted a specialized custom double end trim saw tailored specifically for Dow Chemical, aimed at precisely cutting particulate filters. This machine, engineered with robotic loading capabilities, was entirely enclosed to ensure safety and efficiency. It was adept at trimming two faces in parallel with a remarkable precision of within 0.002".

Explore More of Our Work

For more information about our services and capabilities, please contact us today at 920-230-2240.